The finished article. The cost of professionally treating the room, and having acoustic treatment custom-built, came to slightly less than that of the monitoring system which benefits from it!

The finished article. The cost of professionally treating the room, and having acoustic treatment custom-built, came to slightly less than that of the monitoring system which benefits from it!

Getting good results in a small space isn't easy — but it is possible. And if you're the Technical Editor of Sound On Sound, it's also essential!

In a job like mine, I get to see a very large number of both professional and home studio spaces. Often, the most significant difference is that the latter either have too little, or quite inappropriate, acoustic treatment. So, when Paul White and I do our Studio SOS visits we can usually make a very considerable improvement just by introducing a few thoughtfully placed and good-quality acoustic panels.

I'm not entirely sure if my studio space should count as a professional or home setup — I generally work from home, and all the practical compromises of everyday domestic life affect me and my studio environment just as much as everyone else! Consequently, the room in which I've typed articles for this magazine over the last decade or so, and where I audition most review equipment, hasn't really been the model of acoustic excellence that perhaps it should have been. In my defence, though, I've heard a lot worse elsewhere, and I have become very familiar with my room's particular foibles. Perhaps more importantly, I have other rooms, both at home and in 'friendly' local studios, which I use regularly for critical listening, too. Nevertheless, I knew my home studio could be a lot better if I really put my mind to it, and the 'Do as I say, not as I do!' aspect has never sat comfortably.

Like many reading this, I suspect, I'd long had outline plans in my head for building a 'better room', but they mostly required moving to a new home that could provide a larger and more suitable starting point! Inevitably, though, family circumstances never evolved quite as expected, and my relocation plans stalled for almost a decade. Finally, the stars started aligning last year and the opportunity to move to an 'ideal home' had finally become a reality... or so we thought!

Unfortunately, when it came down to it, Mrs R and I couldn't agree on exactly what we both wanted, or even where we wanted to move to. So we drew up a list of 'absolutely essential requirements' and quickly realised that our current abode already ticked almost all of those boxes. Consequently, rather than spending money on relocation we tried to think laterally and find ways of repurposing the rooms in our present house, making better use of the existing space, as well as building some additional space to better accommodate our specific requirements.

Defining The Problem

As part of our re-evaluation we considered moving my studio elsewhere in the house, but over the 20 years that we've been here, it had already occupied three different rooms, and its current location was clearly still the most sensible and practical choice.

The main restriction in treating the acoustics as I would have liked was a lack of wall space, because my ever-growing collection of technical reference books and magazine archives — to which I refer constantly as part of the process of reviewing equipment and writing articles — were accommodated on five sizeable bookcases along one side of the room. My large collection of reference audio equipment was housed mostly on a large shelving unit on the opposite wall, and while this arrangement of furniture provided some limited absorption and diffraction, it really didn't do anything useful towards controlling the inevitable low-end issues! So the first step to acoustic nirvana had to be to relocate all the books...

As a family, we like books and have a lot of them, so we decided to convert the 'box room' into a proper 'library'. This turned out to be a genius idea! When I'm researching for SOS now, I really like the tranquillity and focus that comes from sitting in a winged-back leather armchair surrounded by oak bookcases, usually with Radio 3 playing gently in the background... and no chance of hearing the office phone!

When I'm researching for SOS now, I really like the tranquillity and focus that comes from sitting in a winged-back leather armchair surrounded by oak bookcases, usually with Radio 3 playing gently in the background... and no chance of hearing the office phone!

The Cunning Plan

With the bookcases and equipment shelves removed from the studio, addressing the acoustics in a professional way became a realistically achievable goal, and I started by identifying my precise requirements and sketching some ideas. It's probably worth explaining at this point that my studio is not typical of most home studios. I don't need to record acoustic instruments or vocals, for a start, or share the space with multiple musicians at the same time. I do record keyboards in it, though, and the odd podcast and video, so it's closer to being a small mastering studio than anything else, with a focus on being able to easily patch equipment for comparative and measurement purposes.

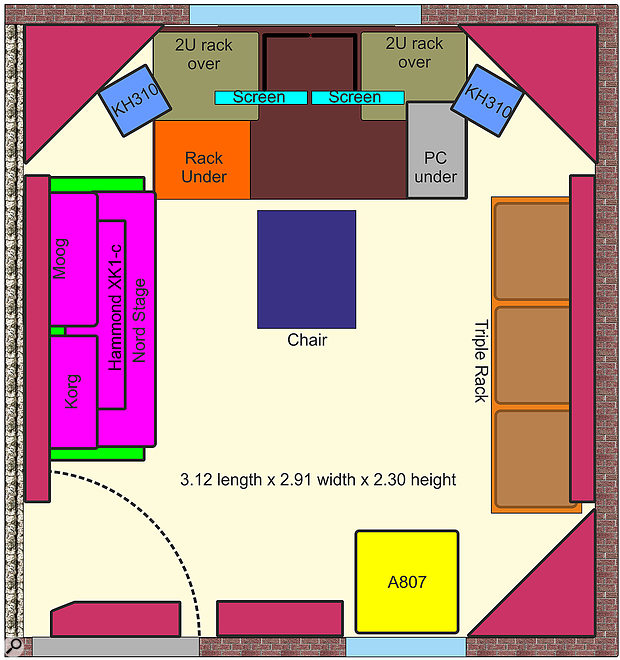

A plan view of the final studio layout.

A plan view of the final studio layout.

Primarily, then, the room needed to provide the best possible stereo monitoring environment, both for auditioning review equipment and also for the editing, mixing and mastering work I occasionally undertake. I also wanted the option to reinstall my surround monitoring system at a later date, so I needed a relatively dead room with a consistent soundscape, and a very well controlled low end.

That last point would be the main challenge, as is so often the case, because the primary disadvantage of my designated room is its size and shape. The worst possible configuration, from an acoustic point of view, is a small cube, and my room is alarmingly near that, with floor dimensions of 3.1 x 2.9 metres with a ceiling height of 2.3 metres. There's also a door in one corner and windows on two opposite walls. Three of the walls are plasterboard dabbed onto concrete blocks, while the other is a stud partition. The floor is wooden laminate on concrete (block and beam), and above the plasterboard ceiling is a heavily lagged roof void.

Experience from countless Studio SOS visits has taught me that getting anything like an even bass response in a room like this is a big challenge, and the previous room incarnation certainly suffered from some bass peaks and dips, and a noticeable lack of bass whenever I leaned back in my chair! So, I knew I would need to prioritise some seriously large-scale bass trapping to achieve reasonable low-end uniformity.

Help Wanted

I would describe my DIY skills as 'adequate', but I wanted my room to look 'professional' and I know only too well from first-hand experience just how hard and time-consuming it is to make DIY acoustic panels look as good as the professionals can manage. Also, given the persistent nature of monthly magazine production, I was very keen to minimise downtime during the refit. I employed these feeble excuses as justification to buy ready-made acoustic panels that I could install quickly over a week to get back up and running as quickly as possible, and started trawling the websites of all the familiar acoustics suppliers, both in the UK and overseas, to create a shortlist of suitable products. Then I plotted how best to position them (and all the rest of the furniture and equipment) on a scale floor plan, and soon came up with what I thought would be a pretty reasonable — albeit moderately expensive — solution. I budgeted about the same as the cost of my Neumann KH310 monitors (£3000), although had I been able and willing to build all the panels myself it would have come in at less than half that.

My outline plan was originally based upon the idea of a new custom-built desk occupying the front of the room, with a pair of 19-inch racks extending down either side of the room, and my keyboards at the back. I decided the acoustic treatment should comprise two large bass traps in the front corners, either side of the window, plus large broadband absorber panels at the mirror-points on each side, with more panels hanging on the door and on the back wall either side of the rear window. There would also be a large ceiling cloud with built-in lighting.

Although I was confident that my plan and acoustic product choices would work reasonably well, this was going to be a significant investment and I would have only a limited ability to change things after the installation, so I thought it wise to seek a second opinion and 'sanity-check' from my good friend Max Hodges. I came to know Max through his former role as a volunteer moderator on the SOS Forum, and his expertise as a studio designer and acoustician made him the perfect sounding board for the practicality of my plans. I am pleased to report that he 'approved' of my initial design (phew!), but he was confident that significantly better results could be obtained if I used custom-made corner bass traps instead of the off-the-shelf ones.

Thankfully, Max offered to design these traps for me so they would fit perfectly from floor to ceiling, thereby maximising their performance, and his bespoke designs would include an option to fit limp-mass membranes to enhance their low-end performance even further, if necessary. Since it turned out that this customised solution wouldn't actually add much to the overall cost of the project, it was a no-brainer to follow Max's suggestions, and I was — and remain — very grateful for his generous design inputs. The small down side was that it would take some time to have these custom bass traps professionally built.

I ended up commissioning RPG-Europe to construct the custom corner panels along with the other absorbers and cloud panels. The company's MD, Mathew Moule, was extremely helpful, and although the manufacturing and shipping took longer than any of us had expected for various unforeseen reasons, the superbly successful finished results mean I've long since forgotten any passing frustrations.

Corner Bass Traps

As will be familiar to anyone who has ever attempted domestic DIY, none of my room's walls, floor or ceiling were perfectly straight, square or level, and so each of the three custom corner bass traps had to have slightly different dimensions. Yes, three corner bass traps: Max's scheme introduced a third one in the rear right-hand corner where I had originally planned standard panel absorbers!

This plan view shows one of the two main bass traps in the front corners, behind the loudspeakers.

This plan view shows one of the two main bass traps in the front corners, behind the loudspeakers.

The two front corner traps are huge, measuring around 1025mm wide and stretching 725mm along each wall. They are constructed from 150mm-thick Owens-Corning OC703 rigid fibreglass with 45-degree chamfers to the inside vertical edges and rebates at the top and bottom to accommodate the existing skirting board and ceiling coving. Their height is about 20mm less than the floor-ceiling dimension, to enable them to be stood up and manoeuvred in the room, and they are covered in Camira Lucia acoustic fabric.

Naturally, RPG-Europe build their panels to exactly the same specifications, and with the same materials, as the original American company — hence the use of OC703 acoustic fibreglass, which is a relatively rare product in the UK. One of the benefits of this material, though, is that it can be cut and shaped easily, and its semi-rigid surface holds its shape, unlike panels made of mineral-wool slabs which can sag over time unless well supported internally.

The choice of fabric is a personal one, obviously, but should be given some careful thought. Just before the room's makeover I had repainted the walls in a warm off-white to keep it looking bright and spacious, and chose a burgundy red Lucia fabric called Calypso for the corner and door panels to make a bit of a visual statement. In contrast, the mirror-point and ceiling panels were all finished in a cream-coloured fabric called Oyster to help reduce their visual impact.

RW3 Rockwool wedges stacked up, ready to have the corner panels with barrier matting positioned in front of them.The dimensions of the bespoke corner panels provide a space behind to accommodate a 'superchunks'-style floor-to-ceiling stack of triangular mineral wool wedges. I used two packs of Rockwool RW3 (60kg/m3) to provide wedges for all three corner traps, initially cutting four large triangular pieces from each 1200 x 600 x 100 mm slab. These each had a long (front) dimension of 600mm with sides of 425mm each. The remaining off-cuts from each slab cunningly turned out to be the perfect size to cut into wedges for the smaller rear-corner bass-trap. It was almost like Max had designed these things before...

RW3 Rockwool wedges stacked up, ready to have the corner panels with barrier matting positioned in front of them.The dimensions of the bespoke corner panels provide a space behind to accommodate a 'superchunks'-style floor-to-ceiling stack of triangular mineral wool wedges. I used two packs of Rockwool RW3 (60kg/m3) to provide wedges for all three corner traps, initially cutting four large triangular pieces from each 1200 x 600 x 100 mm slab. These each had a long (front) dimension of 600mm with sides of 425mm each. The remaining off-cuts from each slab cunningly turned out to be the perfect size to cut into wedges for the smaller rear-corner bass-trap. It was almost like Max had designed these things before...

To hold the stacked mineral-wool wedges in place, a pair of wooden quadrant mouldings were glued and pinned vertically to each wall, and the corners of the triangles were tucked in, with the density of the mineral-wool being sufficient to hold them in place. The large RPG front panels aren't permanently fastened to the wall, either; their sheer weight and the friction from their 45-degree edges seem to be perfectly sufficient to hold them firmly in place, although springy cardboard wedges wrapped in Camira material, which fill the small gaps at the top, help too.

As the diagram shows, there is sufficient space between the front of the mineral-wool wedges and the back of the OC703 panel to hang a heavy loaded-vinyl sheet — the aforementioned 'limp-mass membrane'. Each membrane sheet was cut to fit precisely between the side walls, and almost reached the floor, leaving just a couple of millimetres all round so it remained free to move, with the top of the sheet wrapped around and stapled to a wooden batten screwed to the back of each panel at the very top. This configuration ensures the membranes hang in free air.

This shot of the rear of the corner panel shows the limp mass vinyl suspended behind it.No project ever goes perfectly to plan, though, and I'd have to say fitting the limp-mass membranes was easily the most difficult element in my room's construction — but only because delays in receiving the correct loaded-vinyl sheet material meant the room was in use with the corner panels already in place by the time it arrived! As a result, the panels had to be taken down and the membranes fitted to them while there was a lot of other equipment still in the room, leaving very little floor space or elbow room. However, with Max's considerable practical experience, extraordinary tenacity, and only a moderate amount of profanity, we got the job done!

This shot of the rear of the corner panel shows the limp mass vinyl suspended behind it.No project ever goes perfectly to plan, though, and I'd have to say fitting the limp-mass membranes was easily the most difficult element in my room's construction — but only because delays in receiving the correct loaded-vinyl sheet material meant the room was in use with the corner panels already in place by the time it arrived! As a result, the panels had to be taken down and the membranes fitted to them while there was a lot of other equipment still in the room, leaving very little floor space or elbow room. However, with Max's considerable practical experience, extraordinary tenacity, and only a moderate amount of profanity, we got the job done!

The rear corner bass trap had to be narrower than the front pair because of the rear window, measuring 750mm across the front and extending 450mm along each wall. At 1.85 metres high, it was also less tall, to avoid obscuring the room's PIR alarm sensor. Nonetheless it was built in exactly the same way, but topped with a 100mm–thick triangular panel of OC703 wrapped in Camira Lucia. Smaller RW3 mineral-wool wedges were installed behind up to the full height and secured between quadrant strips just as before, and although we chose not to install a limp-mass membrane in this panel, one could be added later if deemed necessary.

Again, this corner panel is not fixed directly to the wall, but the top wedge panel is prevented from lifting by a couple of quadrant strips nail-gunned and glued horizontally on the wall above it, and this ensures the panel can't move. These arrangements mean there are no visible fixings for any of the three corner panels, yet the whole lot could be removed very quickly and easily, if necessary, with only a minor paint patch-up being necessary.

The finished corner bass trap looks smart and does an effective job. This photo also shows the attractive racks and desks made by Chunky Studio Furniture.

The finished corner bass trap looks smart and does an effective job. This photo also shows the attractive racks and desks made by Chunky Studio Furniture.

Wall & Mirror Panels

The side mirror-points were dealt with using a couple of custom-made landscape-format broadband absorbers measuring 100mm thick, 1800mm wide and 600mm high. Constructed from OC703 again, and wrapped in Camira Lucia Oyster fabric, these panels came with a pair of angled aluminium rails attached horizontally to the rear and loose matching rails for fitting to the wall. We mounted these on wooden battens fixed to the walls, so that once hung there was a gap between panel and wall of 40mm. A similar absorber panel, but in portrait format and measuring 1200 x 600 x 100 mm, was mounted using the same technique in the middle of the rear wall.

Mounting the side panels away from the walls introduces an air gap and a useful increase in absorption.Doors are frequently located in awkward places and my room is no exception, with the door positioned in the rear left corner. As I obviously couldn't install a corner trap to match the other three, the best compromise was to hang a panel directly on the door. However, the panels couldn't be too thick, as that could prevent the door opening wide enough to get equipment and people in and out easily! In the end Max and I decided to use two panels, one above and one below the door handle, which meant specifying two identical panels of 800 x 800 x 50 mm thick, covered again with the red Lucia Calypso fabric. This time we fixed the aluminium mating strips directly onto the door, spacing the panel out by just 20mm. We had considered having the panel inside edges chamfered at 45 degrees to assist in maximising the door's opening angle, but that turned out to be unnecessary as it was possible to slide the panels left, away from the wall and slightly overlapping the door jamb, which allows a sufficiently wide opening anyway.

Mounting the side panels away from the walls introduces an air gap and a useful increase in absorption.Doors are frequently located in awkward places and my room is no exception, with the door positioned in the rear left corner. As I obviously couldn't install a corner trap to match the other three, the best compromise was to hang a panel directly on the door. However, the panels couldn't be too thick, as that could prevent the door opening wide enough to get equipment and people in and out easily! In the end Max and I decided to use two panels, one above and one below the door handle, which meant specifying two identical panels of 800 x 800 x 50 mm thick, covered again with the red Lucia Calypso fabric. This time we fixed the aluminium mating strips directly onto the door, spacing the panel out by just 20mm. We had considered having the panel inside edges chamfered at 45 degrees to assist in maximising the door's opening angle, but that turned out to be unnecessary as it was possible to slide the panels left, away from the wall and slightly overlapping the door jamb, which allows a sufficiently wide opening anyway.

Fortunately, I don't have to worry about noise getting in or out of the studio, so I haven't needed to replace the existing hollow-cored door with a solid version, and neither have I had to fit full acoustic edge seals and a compression latch to the door. However, these would all be essential requirements for any installation where noise leaking in or out could be an issue.

The last acoustic panel to install was the ceiling cloud: another bespoke panel measuring 1200 x 1800 x 100 mm thick, and fitted with five LED down-lighters arranged in a quincunx pattern [like the '5' pattern on a six-sided die. There, saved you a trip to Google — Ed.]. Multi-colour LED light strips were fixed into aluminium U-channels around the top edges of the panel with the idea of throwing some mood-light around the ceiling. The down-lighters and LEDs are wired into an 'Energenie' remote-controlled five-socket plug-board, allowing different lighting configurations to be selected as appropriate. Those top aluminium channels were also pre-drilled in the corners to accept support wires, which were looped through eye-bolts set into the ceiling joists and secured using elegant 'Gripple' clips, which allow the ceiling cloud to be positioned and levelled at any desired height. In my case, the top of the cloud is around 180mm below the ceiling.

Window Treatment

Fitted like secondary double glazing, this Clearsorber panel cleverly absorbs low- and mid-frequency energy without blocking natural light.Dealing with window reflections is always difficult, but doubly so in domestic spaces. In most professional studios, windows are blocked with tight-fitting broadband absorber panels to maximise sound isolation, but I don't need to worry about isolation, and I wanted to keep the natural daylight anyway. I had originally planned to adopt a Paul White recommendation of using wooden Venetian blinds as ad-hoc diffusers. However, yet another of Max's brilliant suggestions was to install 'DeAmp Clearsorber' panels instead.

Fitted like secondary double glazing, this Clearsorber panel cleverly absorbs low- and mid-frequency energy without blocking natural light.Dealing with window reflections is always difficult, but doubly so in domestic spaces. In most professional studios, windows are blocked with tight-fitting broadband absorber panels to maximise sound isolation, but I don't need to worry about isolation, and I wanted to keep the natural daylight anyway. I had originally planned to adopt a Paul White recommendation of using wooden Venetian blinds as ad-hoc diffusers. However, yet another of Max's brilliant suggestions was to install 'DeAmp Clearsorber' panels instead.

No, I'd never heard of Clearsorber panels either, but apparently they are widely employed by architects for 'reverberation control' in commercial building atriums and other industrial buildings with acoustically reflective surfaces. Essentially, a Clearsorber panel is just a sheet of acrylic or polycarbonate, and so can be produced with clear, translucent, opaque or coloured finishes, and can even be printed with images or logos. The thickness varies from 2 to 20 mm depending on the panel size — thicker being necessary for larger panels to maintain structural integrity.

Hundreds of 'micro-perforations' are laser-cut into the sheet, usually in the form of thin slots in a convenient pattern, and it is these slots that deliver the Clearsorber's remarkable acoustic performance by building on the idea of a Helmholtz resonator. Instead of incident sound waves building a high pressure boundary layer on the surface and being reflected, that pressure ebbs away because the air leaks through the slots into the air cavity behind, so forming a kind of self-damping 'lossy' boundary layer instead. As a result, a Clearsorber sheet provides very effective absorption through the low- and mid-frequency ranges, with an absorption coefficient of between 0.4 and 0.6 from about 80Hz up to 800Hz (depending on the precise design spec and installation parameters), which is really quite remarkable, and very useful!

I'd never heard of Clearsorber panels either, but apparently they are widely employed by architects for 'reverberation control' in commercial building atriums and other industrial buildings with acoustically reflective surfaces.

This ingenious technology is patented by a Norwegian company called DeAmp, but is available from specialist retailers including RPG, both in America and Europe. Installing a Clearsorber panel is much like a secondary glazing panel with an air gap between the sheet and the window glass. For my room, I chose an opaque panel for the back window as that looks out onto the driveway and I didn't want the studio equipment to be on public show. A larger clear panel was specified for the front window to maintain a view of the garden, and both panels were supplied pre-cut to the exact size required. I built two very simple wooden frames to secure them into the window recesses, and I have to say I'm really impressed with how effective these panels actually are — it's a genius idea!

Equipment Installation

With the acoustic treatment in place, I was able to install the desk and racks which I'd commissioned from Guy Mitson at Chunky Studio Furniture in Somerset. These are built from reclaimed scaffold planks, which is good for the environment, attractive to the eye, incredibly solid and sturdy, and Guy is very accommodating about custom-building to specific requirements. The desk is high enough that I can work sitting or standing equally well, while the two racks (one three bays wide and the other a single bay) were designed to place the tops at eye level when seated, to make it easy to see the controls and displays of review equipment under test. That translates into 23U of space in each rack. Of these, the bottom 6U is vertical so I could fit rack drawers for equipment storage, while the remaining space is angled slightly backwards.

The original plan was to have these racks either side of the desk. I had anticipated that, when full of equipment, they would be acoustically reflective, potentially degrading the listening position quite badly. For that reason I ordered an extra pair of absorber panels that could be positioned over the racks when needed for critical listening. These panels were both 400mm tall by 50mm thick, but one was 1500mm wide and the other 800mm to fit the different racks. Just to be different I specified these in a light blue Lucia fabric called 'Scuba'.

As I'm sure we've all found, what looks to work perfectly on paper often doesn't actually work as well in practice. When I started to install the racks and equipment in the studio it soon became apparent that having the keyboards at the back wasn't as convenient as I'd anticipated, and the smaller rack bay was visually much more imposing than I'd expected, too. Consequently, I've relocated the keyboards to the left-hand side of the room and the three-bay rack to the right, with the single–bay rack being evicted. Squeezing all the equipment into the three-bay rack meant losing some planned storage drawer space, but the room benefits overall — and I've reduced the potential reflection sources in the process, so the extra blue panels probably won't be needed for their original design purposes. That said, they are very handy to have as movable acoustic absorbers (and as backgrounds for equipment photography!), and currently they are stored out of the way above the mirror point absorbers (where the surround speakers will eventually go).

Computer monitor screens can be an acoustical headache, often causing unwanted reflections and diffractions that degrade stereo imaging, so I've mounted my pair of screens on an Ergotron dual arm bolted directly into the desk so that the screens can be easily flattened and/or moved well out of the way when necessary. They can also be raised when I want to work standing up, and rotated to portrait or landscape orientations as required.

Final Thoughts

This studio makeover was long overdue, and had I known our relocation plans would be scrapped I'd have done it years ago. The room certainly looks very good now, it's a much nicer environment to work in, and I've found the ability to work seated or standing to be surprisingly useful, too.

Although the corner trapping takes up quite a lot of floor space in what was a small room to start with, the improvements in bass uniformity and stereo imaging precision are enormous — even more than I had hoped for. I no longer have to be careful where I sit, bass runs are deliciously even, and I've noticed a surprising bass extension — so the sacrifice in furniture/equipment space has been well worth it given the substantial acoustics benefits. Interestingly, since completing the makeover I've also rarely needed to check the low end using headphones, because what I'm hearing from the speaker is so much more reliable.

Obviously, buying custom acoustic panels is a relatively expensive solution, but even so the whole shebang cost less than the Neumann monitor speakers, and that seems like a reasonable balance to me. And, as I said, had I taken the DIY route the cost would have been substantially lower still, but with a very similar overall performance although with my DIY skills it probably wouldn't have looked as good. So, now I really can claim: Do as I say, and do! And I can demonstrate exactly why it pays to invest in decent acoustic treatment with effective bass trapping.

How It All Fits Together

My whole studio setup is based around a Crookwood mastering console. Its remote control pod sits in the middle of the desk providing analogue and digital source selection, signal routing and format conversion, along with comprehensive audio monitoring facilities. It has three analogue and three digital insert points, complete with level matching and an M–S matrix, which I use mostly for comparing review products with my references. Additional digital I/O is provided by a Z‑Sys 8x8 'digital detangler' and analogue I/O with an old SSL X‑Patch. A Yamaha DM1000 console now lives on a pull-out shelf above some rack space in the left-hand side of the desk housing a patchbay and various ancillaries. In the left pod on top of the desk is a patch panel for easy connection of review gear, and a switched MDU to power various combinations of equipment as necessary. The right-hand pod carries my beloved Drawmer Masterflow processor and a Lexicon PCM90, where they fall easily to hand when mastering.

On top of the left pod is a traditional BBC-style twin-PPM (old habits die hard!), which follows the monitoring selection, along with a DK Technologies MSD600M++ metering system, which is routable but normally follows the digital recording output from the Crookwood. The main monitors are Neumann KH310s, which are currently on Zaor adjustable speaker stands while I await the arrival of custom designed stands which will move the speakers a bit closer together. Some uber-cheap PC speakers sit behind the display screens as a 'consumer reference'. I have yet to install my mono reference/centre speaker.

The centre bay of the triple rack is taken up almost entirely with signal patching, but also houses the Crookwood hardware and, in the back (to minimise the fan noise), the Audio Precision test set and Pico digital oscilloscope interface. The right-hand bay houses Drawmer and Aardvark master clocks and associated patching, as well as an RME ADI4-DD digital adaptor converting between ADAT and AES3 formats. A mutant Revox PR99 MkIII reel-to-reel is fitted with a quarter-track replay head in place of the record head, supplementing the standard half-track replay head and allowing playback of vintage consumer/domestic tapes, while a Studer A807 half-track stereo machine — fully capable of recording — sits on a trolley at the back of the room. Dolby A codecs in the bottom of the bay are patchable to either machine via the SSL X-Patch, while an Apogee PSX-100 converter provides a means of routing digital signals in or out of the X-Patch. A DAB radio receiver provides a useful source of speech and music for testing purposes, as well as background entertainment.

The left-hand bay contains an API Lunchbox rack at eye height for testing 500-series modules, with Sony R7 and TC Electronic M-One XL digital effects units. A legacy CD recorder sits above a multi-format disc player, which is for burning and checking customer preview discs. A Plextor disc drive hooked into the computer is also used for comprehensive CD/CD-R analysis.

GML 8304, SSL VHD, and Audient ASP880A mic preamps in this bay are mostly used for comparative purposes, although the external A‑D input on the Audient is also used to digitise the surround outputs from the HHB universal disc player. A Drawmer A2D2 and Benchmark DAC1 provide more assignable analogue/digital conversion, while a JK‑Audio telephone interface provides the ability to record telephone interviews. Taking up useful drawer space at the bottom of the rack is my trusty Powertran digital delay line, which I built in 1982 and can't bear to discard... so I recently upgraded it with a balanced input and output so it can be easily patched with everything else!

To the left–hand side of the desk are Hugh's keyboards on a Sequenz stand: a Nord Stage Classic (rev C), a Hammond XK-1c, a Korg MS20 (kit), a Moog Sequential CV, and a vintage Yamaha RY20 drum machine.

To the left–hand side of the desk are Hugh's keyboards on a Sequenz stand: a Nord Stage Classic (rev C), a Hammond XK-1c, a Korg MS20 (kit), a Moog Sequential CV, and a vintage Yamaha RY20 drum machine.

To the left–hand side of the desk is my stack of keyboards on a Sequenz stand. Currently these comprise a Nord Stage Classic (rev C), a Hammond XK-1c, a Korg MS20 (kit), a Moog Sequential CV, and a vintage Yamaha RY20 drum machine! These are all connected to the Yamaha DM1000 console via the patchbay, so I can practice without having to boot up the computer, but they are also routed into the computer via the console's ADAT interface.

Finally, a broadband modem and related equipment is mounted on a shelf above the door with cable hangers underneath for storing copious assorted patch cables. All the computer equipment, including a stack of NAS storage boxes and printer next door (to keep the fan noise out) are powered from a UPS under the desk.

Reference Links

Acoustic Products:

www.rpgeurope.com/products/product/allproducts.html

Studio Furniture:

https://chunkystudiofurniture.co.uk

Window Panels:

Studio Consultancy:

Max no longer offers studio design services professionally, but he has been known to help those who catch him on a full moon with the correct password: