Cranborne say their Brick Lane is the fastest compressor in the West — but it’s also capable of modelling the characteristics of classic opto, FET and valve units, and much more.

In just seven years, Cranborne Audio have built a very fine reputation for their steadily expanding range of innovative, high‑performance products. Cranborne’s ethos is to push the boundaries of what’s possible with analogue audio electronics, both technologically and in terms of what the user can achieve with their products. Their approach has resulted in remarkably transparent products with exemplary specifications, combined with the ability to introduce delicious musical character at the twist of a knob or flick of a switch.

For example, the company’s debut product, the Camden mic preamp (reviewed in SOS October 2018), remains unquestionably amongst the finest mic preamps available at any price, yet it also offers a glorious range of vintage tonalities if required. Their Carnaby EQs (the latest being the Carnaby HE2, reviewed in SOS October 2024) offer a new approach to EQ and tone‑shaping. And talking of exemplary specs, their 500‑series racks incorporate exceptional digital conversion that comfortably outperforms many high‑end mastering converters.

Overview

The latest addition to Cranborne’s product portfolio is their first compressor — a single‑slot, 500‑series mono module that continues the company’s predilection for London‑inspired names, called the Brick Lane. Its full title, though, the Brick Lane 500 Modal PWM Compressor, hints that this is no run‑of‑the‑mill compressor...

Whereas traditional analogue compressors might employ an electro‑optical cell, vari‑mu valve, FET or VCA as a gain‑controlling element, the Brick Lane 500 uses a sophisticated pulse width modulation process instead (see box). This technology has been employed in dynamic range compressors before, but remains relatively unusual; it offers significant technical benefits over more traditional solutions, but it’s also very complicated and, in the past, expensive to implement. Its implementation has therefore been restricted mostly to high‑end manufacturers like Dave Hill/Crane Song, George Massenburg Labs and Great River. Nevertheless, PWM technology theoretically affords the very best technical performance that an analogue compressor can deliver, particularly in terms of speed, ultra‑low distortion (especially at high gain reductions), control linearity and consistency. And, since digital side‑chain control suits the technology very well, this approach can also allow unrivalled operational versatility.

So, right off the bat, the PWM technology (carefully optimised by Cranborne’s team, which is no small challenge, actually!) makes the Brick Lane an inherently ultra‑clean, transparent, and stunningly fast compressor. And that’s great, if that’s what you need — but we all know that compression is often much more about musicality and character than it is about speed and precision, so Cranborne have conceived the Brick Lane to be configurable to accurately emulate a variety of conventional compressor technologies, too.

The Brick Lane 500 includes a novel variation on the ‘look‑ahead’ idea to control fast transients without distortion.

Looking Forward

There’s some genuine innovation here: the Brick Lane 500 includes a novel variation on the ‘look‑ahead’ idea to control fast transients without distortion. Remember, this is an analogue processor, so the sort of look‑ahead we might be used to in plug‑ins isn’t available. And rather than pass the signal through a delay line to allow the side‑chain a sneak preview (which is how the HUM Audio LAAL’s analogue look‑ahead function works, but introduces latency), the Brick Lane uses a new digital technology called ‘negative group delay’. This fascinating science essentially preempts transient peaks by a quarter‑wavelength (at any frequency). That might not sound much but it’s enough for very effective transient control with a near‑zero attack time, allowing true brickwall limiting when required.

Like other Cranborne products, the Brick Lane compressor also incorporates its own form of saturation processing. The Camden preamp has its Mojo control, for example, while the Carnaby EQ has its Harmonic EQ, and in a similar vein, the Brick Lane offers the user a Stress control. This feature involves a multiband saturation circuit that, combined with other compressor parameter variations, replicates the musical characteristics associated with different analogue compressor technologies. Six distinct flavours are available, with the Stress knob adjusting the strength of the carefully tailored saturation effects.

Also, like the Carnaby Harmonic EQ, two or more Brick Lane compressors can be linked for stereo or multi‑channel operation in two ways. A 3.5mm TRS socket near the back of the module caters for wired connections between modules, but most users will employ the company’s ingenious OptoSync feature where an LED transmitter on the right of each module near the front panel beams across to a corresponding opto‑sensor on the left of adjacent modules, sharing control information. The leftmost module in the OptoSync group determines control settings for all linked modules. The main benefit of the wired alternative is that it allows the two modules to be placed anywhere in the host 500‑series rack — it might be more convenient, for example, if you were to assemble two identical channel strips, each comprising preamp, EQ and compressor.

Control & Operation

The Brick Lane’s control panel is styled like other Cranborne 500‑series modules, with a quintet of large, gently detented knobs arrayed vertically to the left of the panel, and various displays, switches and a smaller knob to the right.

A Brick Lane installed in an API 500‑6b Lunchbox rack. Note the Stress control beneath the meters, and the seven operating modes below it — for more about those, see the ‘Compression Modes & Emulations’ box.

A Brick Lane installed in an API 500‑6b Lunchbox rack. Note the Stress control beneath the meters, and the seven operating modes below it — for more about those, see the ‘Compression Modes & Emulations’ box.

The input level is set with the top rotary control over a ±20dB range, while the threshold knob underneath is scaled simply from Min to Max. A large dual bar‑graph meter to the right complements these primary level controls by showing input level (post input trim) on the left meter and gain reduction (GR) on the right. The input meter spans ‑24 to +24 dBu, with green LEDs up to +15dBu, then yellows at +18 and +21 dBu, and red at +24dBu. The GR meter descends from the top, covering the range from 0.5 to 15 dB, with the finest resolution in the upper half — the middle of the scale indicates 5dB of gain reduction.

Below the threshold control are attack and release knobs, both scaled from slow to fast — the right approach to the labelling, given that their precise values are highly dependent on the chosen operating mode. The last large knob, at the bottom of the panel, adjusts the output level, again spanning a ±20dB range.

The Brick Lane’s compression is activated using a toggle in the bottom‑right corner, and an adjacent LED lights blue when it’s active or white if being controlled by OptoSync (enabled by another toggle just above). A third, centre‑sprung momentary toggle switch above that one controls the Brick Lane’s clever features, responding differently to long and short presses left or right. For example, a short press left cycles through four side‑chain high‑pass filter options (off, 60, 100 or 200 Hz, with LED indicators just below) to reduce the impact of strong bass on the compression process. A long press to the left accesses seven different stereo‑linking modes, indicated by the number of illuminated GR LEDs. The side‑chains can operate independently (unlinked), the loudest channel setting the GR (with two low‑pass filter options), or with the two channels summed to determine the GR (again, with two low‑pass filter options). The filter options are 5.4 or 2.7 kHz and help to smooth gain‑reduction changes in the presence of transients. Another long press left exits this configuration mode.

Flicking the toggle to the right cycles through seven different compressor modes, with LED indications above the switch. These modes are labelled Velvet, Float, Smash, Tame, Glue and Polish — this last with white and blue options (see box). Selecting a mode recalls the appropriate parameters for things like feedback/feed‑forward topology, RMS or peak‑sensing side‑chain, initial compression ratio, knee shape, side‑chain emphasis, and saturation character (amongst other things), as well as optimised ranges for the attack and release controls.

The initial ratio value increases automatically in most modes as the threshold is lowered but it can also be adjusted manually, if desired, via a long toggle press to the right. When this function is accessed the GR meter turns blue, and further short flicks to the right alter the ratio value as indicated on different GR LEDs. Another long press to the right exits this function.

The small rotary control labelled Stress, just below the bar‑graph meter, adjusts the amount of multiband saturation. Fully anticlockwise turns the function off, and rotating clockwise increases the saturation effect for the selected mode. For example, in the Velvet mode the Stress feature introduces a creamy valve‑style saturation with some low‑end thickness, whereas in Float mode Stress smooths out the high end and softens transients. Adjusting Stress in Smash mode adds a bright, aggressive and gritty character, while in Glue mode Stress increases the overall mix thickness. Tame mode is pure ultra‑clean PWM compression and Stress is quite subtle and restrained. In the two Polish modes (these are look‑ahead PWM limiters), Stress changes the character of peak clipping.

It serves no purpose and might end up hidden in the rack... but you have to admire the graffiti‑adorned brickwork aesthetic!

It serves no purpose and might end up hidden in the rack... but you have to admire the graffiti‑adorned brickwork aesthetic!

Additional configuration options can be accessed using a six‑way DIP switch on the upper circuit board. The first switch selects the 3.5mm socket for sync’ing modules instead of the OptoSync facility, and the next two switches determine whether the level trim and bypass switch settings are mirrored on OptoSync’ed units. Switches 4 and 5 decide whether the input and output level controls remain active when the unit is bypassed, while switch 6 accesses the mysterious Enigma mode — for more on that see the separate box.

In Use

Operating the Brick Lane compressor is perfectly straightforward, and the seven compression modes offer more than enough variety and controllability for most applications and requirements. I found it pleasingly easy to extract whatever flavour of compression I wanted for a given instrument, vocal or mix, fine‑tuning settings as desired. It’s just a case of selecting an appropriate emulation mode, setting the threshold for the desired amount of squash, the attack and release controls to suit the material’s rhythm and dynamics, and the Stress control for character. Occasionally I manually changed the ratio value, but I rarely found that I wanted to delve into the nitty‑gritty Enigma parameters — purely because Cranborne have optimised the parameter sets for each mode so incredibly well.

I found it pleasingly easy to extract whatever flavour of compression I wanted for a given instrument, vocal or mix, fine‑tuning settings as desired.

In my view, it’s so creative to choose a suitable‑sounding mode and then adjust the few front‑panel controls while listening to how the music is affected, and far more productive than focusing on too many control parameters and scale numbers, which only distract from the real job in hand.

In terms of sound quality, I can’t fault the Brick Lane at all. Like the Camden preamp, it covers every inch of ground from sublimely clean and transparent to in‑your‑face pumpy aggression, with everything you could ever want in between! If you want to shape drums or rein in a slap bass, the Smash mode will do it well. If you’re tracking vocals, try the Velvet or Float modes. Glue is ideal when Mixing, and the Tame and Polish modes are wonderfully transparent for mastering.

The core strength of PWM compressors is how hard the compression can be driven without audible artefacts, and in that respect I’m hugely impressed with the Brick Lane 500 — particularly in the Tame compression and (blue) Polish limiting modes (which I note both use the triple side‑chain sensing configuration of peak, RMS and long RMS). The Velvet, Float, Smash and Glue modes all represent the key characteristics associated with analogue compressors so effectively that the Brick Lane genuinely can be used for any source, in any mixing or mastering application, and it’s this versatility that makes it a true classic in the making. Highly recommended!

Alternatives

The closest Brick Lane alternative I’m aware of is the Great River PWM‑01 500‑series compressor module, but it’s both more expensive and less versatile than the Brick Lane. Rackmounting PWM compressors are available from Crane Song (the STC‑8 and Trakker) and ART (Dual‑Limiter). George Massenburg Labs made the excellent Model 8900 PWM compressor, but I believe that’s currently out of production. There are also a few niche and DIY homages to the original PYE 4060 design.

PWM Compression: A Primer

While Cranborne’s implementation is novel, pulse width modulation compression itself is not a new technology. It evolved in the late 1960s, when fast transistors became available at low cost. A few compressors employed the PWM technique in the ’60s and ’70s, including the EMT 156 and PYE 4060 — models that now command huge second‑hand prices, and have a reputation for sounding smooth and transparent, with significantly lower distortion at high gain reductions compared with contemporary designs that used other topologies.

Conventional compressors employ a gain‑control element in the signal path to reduce the amplitude of the output signal, as determined by ‘side‑chain’ circuitry, which analyses the signal (either from the input or output) to produce a control voltage that varies the gain reduction. That gain‑control element is usually configured as a continuously adjustable voltage divider, essentially acting as a remote‑controlled volume knob.

In contrast, the PWM concept is a radically different approach. It’s equivalent to an output switch being flicked on and off at an incredibly high speed (typically around 250kHz): when the switch is open, the audio signal’s energy is allowed through to the output, and when it’s closed, it isn’t. If the ratio of open and closed durations is varied for each switching period, a precise amount of audio energy (and hence signal volume) is allowed through to the output. For example, if the pulse width is 100 percent, then all of the source energy is passed to the output and there is no attenuation, whereas if the pulse width is reduced to 50 percent of the switching period, only half the energy is passed, giving a 6dB reduction in level.

This is clearly a form of audio sampling, yet the pulse‑width modulated samples are never quantised and so never become ‘digital’ — it remains a fully analogue signal path. However, both anti‑alias and reconstruction filtering are still required to adhere to the Nyquist theorem. Those early PYE and EMT compressors (and some more modern PWM compressors too) rely on very complex analogue circuitry to control the PWM process. By contrast, the Brick Lane uses a digital microcontroller that affords incredibly accurate and consistent control, but also allows compression parameters to be modelled in myriad ways to perfect absolutely precise and transparent dynamic control — or to emulate the subtle musical imperfections of vintage compressors.

Compression Modes & Emulations

The Brick Lane features seven different operating modes, which have been designed to emulate more traditional compressor topologies:

- Velvet represents the characteristics of a vari‑mu valve compressor in a feedback topology, with RMS sensing, an initial 2:1 ratio, and programme‑dependent release, giving a smooth, warm charm.

- Float emulates a typical gentle 3:1 opto‑compressor, again with RMS sensing, fast attack but with a 60ms lag, two‑stage programme‑dependent release, and side‑chain pre‑emphasis creating a brighter character than the Velvet mode.

- Smash replicates a stiff, feed‑forward, 8:1 FET compressor with fast peak detection, giving a punchy, dynamic sound character.

- Tame mode is another feed‑forward configuration, with a 4:1 ratio and a wonderfully smooth triple side‑chain sensing format combining peak, RMS and long‑RMS sensing. This is effectively a pure PWM compressor with a stunningly clean, transparent character, but retaining tight control of transients.

- Glue is a typical bus‑style feed‑forward compressor with a 2:1 ratio and RMS sensing intended for mixing and mastering, creating a very cohesive sound and a smooth “transformery warmth”.

- The two Polish modes are intended for peak limiting in mastering, using a feed‑forward topology with infinity:1 ratio. The white version provides very fast and hard peak limiting with a look‑ahead function for ultimate control of transients, while the blue version has a soft‑knee character and gentler clipping, which sounds more like analogue tape limiting.

Enigma Mode

The Brick Lane’s Enigma functions are enabled using DIP switch 6. Long presses left or right on the mode toggle can then access hidden parameter options to tailor the unit’s sound character to suit specific requirements and preferences. I doubt most users will ever want to meddle, but advanced users — and particularly mastering engineers — may find the adaptability and customisation extremely useful. Of course, a factory reset is available, should this inner tweaking go horribly wrong!

The Enigma functions are quite complex. It’s all explained well in the user‑manual but, as an overview, there are options for adjusting the peak‑clipping character, side‑chain high‑frequency emphasis settings, and side‑chain detector modes (RMS, peak, and the weighting between the peak and RMS values for the dual modes), compression knee characteristics, progressive weightings for the attack and release times, and multiband crossover and polarity options for the Stress function.

There’s an immense capability here for fine‑tuning the sound character and behaviour of different compressor modes, going far beyond most users’ requirements, but it’s fascinating to see the detailed modelling involved — and Cranborne’s fantastic attention to detail.

Construction & Technical Performance

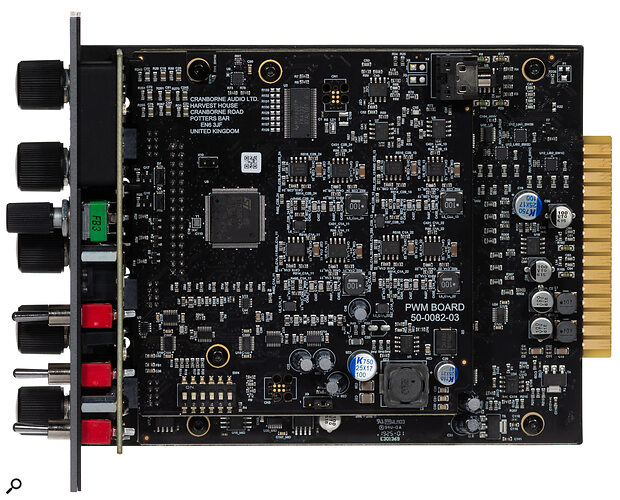

The Brick Lane 500 is constructed to a very high standard, of course, with a main circuit board mounted against a metal side panel and a smaller daughterboard sitting on top. Both boards are covered densely with surface‑mount components including an STM32 ARM Cortex microcontroller, which I gather is the heart of the PWM system. Given the very high‑frequency (250kHz) PWM switching I was surprised that the whole unit wasn’t enclosed in a metal case, but I could detect no interference into adjacent modules in the rack, which is reassuring.

The Brick Lane’s signal path is entirely analogue, but an STM32 ARM Cortex microcontroller lies at the heart of the PWM control circuitry that makes this compressor so incredibly versatile.

The Brick Lane’s signal path is entirely analogue, but an STM32 ARM Cortex microcontroller lies at the heart of the PWM control circuitry that makes this compressor so incredibly versatile.

The published technical specifications are exemplary, of course, with maximum I/O levels of +26.5dBu (the input meter turns red at +24dBu), a frequency response within ±0.5dB from 2Hz up to 80kHz, and a noise floor below ‑100dBu (unweighted). This is all outstanding in a 500‑series module. Other specifications are equally astounding. For example, the fastest attack time (with the look‑ahead mode enabled) is just six nanoseconds, and THD is amazingly low at around 0.00025% at nominal operating levels (with zero gain reduction). In most compressors, distortion rises with increasing gain reduction, but even at 20dB gain reduction the Brick Lane’s THD figure rises only to 0.00085% — such is the benefit of PWM! It seems rather contrary, then, that the Stress control deliberately introduces up to 20% distortion at extreme settings... but it’s nice distortion, so that’s all right!

One spec that raised an eyebrow is the current consumption. This is quoted as 140mA per rail (with a peak requirement of 160mA). It’s by no means the highest we’ve seen, but it does exceed the original API (and current VPR Alliance) specification for 500‑series racks of 130mA per rail. That said, I tested a pair of Brick Lane modules in an original API Lunchbox frame with two preamp modules also installed and detected no problems at all. No doubt Cranborne designed the Brick Lane module for use in their own 500R8 and 500ADAT racks, both of which provide up to 250mA per rail, and many other 500‑series rack manufacturers now use equally generous power supplies, including API’s own ‘high‑current’ racks. So, I don’t believe the current consumption will be an issue in practice, but it’s worth being aware of if using an elderly API 500‑series rack.

Pros

- Astounding technical performance and highly skilful implementation.

- Incredibly transparent PWM compression with beautifully optimised parameters.

- Seven highly effective emulations of traditional compressor topologies, with variable saturation effects.

- Simple control set allowing fast, intuitive operation.

- Comprehensive deep‑dive parameters for detailed customisation.

- OptoSync module control linking.

- Astounding value for money.

Cons

- None.

Summary

Another extraordinarily versatile and great‑sounding product from Cranborne! In the Brick Lane they’ve extracted phenomenal performance and variety from a skilful implementation of sophisticated PWM compressor technology.

Information

£679 including VAT.

Cranborne Audio +44 (0)1707 656500.

When you purchase via links on our site, SOS may earn an affiliate commission. More info...